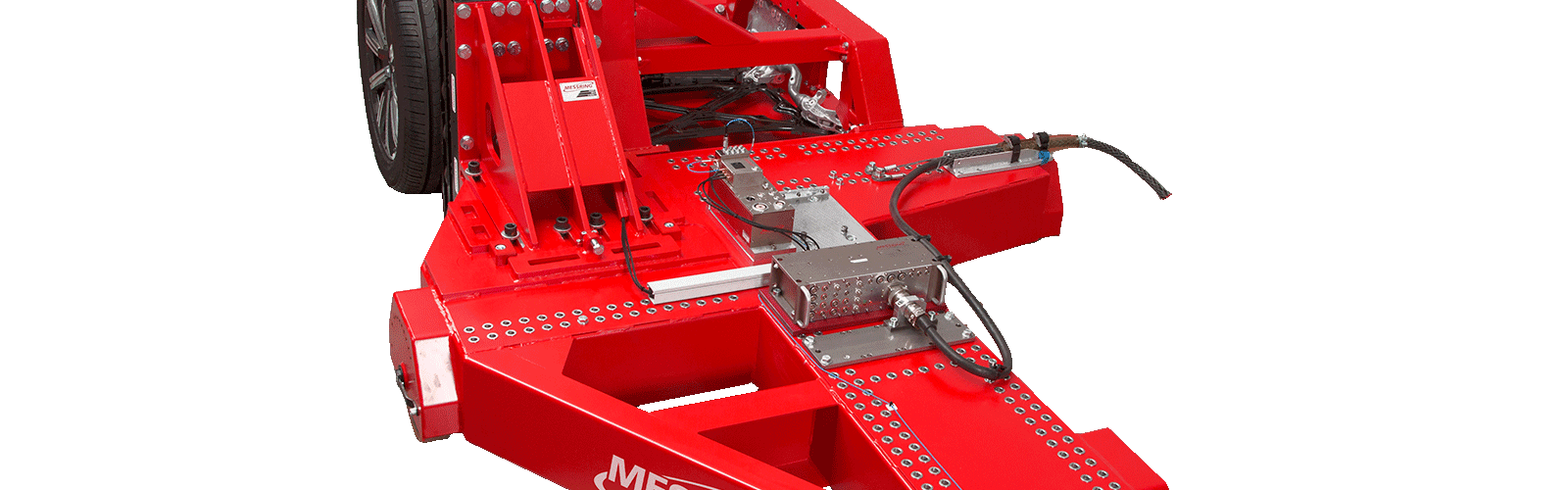

Crash expert MESSRING presents new deceleration sled / The latest development enables specific small overlap test scenarios for chassis without destroying an entire vehicle

Munich, 28. May. 2020 – The small overlap crash test is one of the major challenges for the structural strength of vehicles. One of the main assessment criteria is the intrusion of tires, body and chassis parts into the passenger cabin. With the M=SLED Small Overlap, there is now an option to cost-effectively test critical chassis components that could penetrate the passenger compartment without destroying an entire car body. The ability to examine the crash behavior of the chassis individually can provide important information for further research and development early in the development process and prevent expensive misdevelopments.

Measuring chassis behavior in the wheel housing

The test sled has been designed for use with the MESSRING HydroBrake and is consequently designed to simulate the small overlap test scenario on the left side of the vehicle realistically. The chassis to be tested runs freely rolling on the ground at up to 64 km/h against a load cell wall which is held in the contour of the small overlap barrier and is then decelerated in a controlled process up to the breaking point. Thanks to the additional load cell wall, which is modelled in the shape of a wheel housing and runs on the sled, the resulting forces and deflection of the components in the wheel housing are measured efficiently.

“These measurement results in combination with the high-speed recordings of the crash documentation provide valuable information on how a chassis behaves in a small overlap test,” says Wolfgang Rohleder, Sales Manager, MESSRING GmbH and continues “When and in which order the individual components of the chassis break under critical load has a great influence on the direction of the deflection and thus on the potential for intrusion into the passenger compartment. With the M=SLED Small Overlap we can help vehicle developers to make cars safer and protect road users”.

Construction-wise, the sled can be adapted to different chassis mounts. Furthermore, thanks to the precise and reproducible braking pulses of the HydroBrake, different vehicle loads can be simulated and testing of various vehicle classes and vehicles is possible.