Quite possibly a new record: Takata Romania has continuously been testing seat belts and seat belt buckles on a MESSRING CIS Compact Impact Sled since the end of 2014

Takata Romania has specialized in the production of passenger protection systems. Some 30 COP tests are carried out on seat belts, seat belt buckles, and other safety-relevant components in accordance with the ECE R16 regulation in Arad on a daily basis. “We started out with just one shift and an average of seven tests in 2014. We now work in three shifts with an average of eight tests per shift,” says Milan Novak, Head of the Testing and Validation team at Takata Romania. “The advantage is that the parameters such as pulse and speed are much more consistent on the CIS than on our former sled system. A lot more tests can also be carried.”

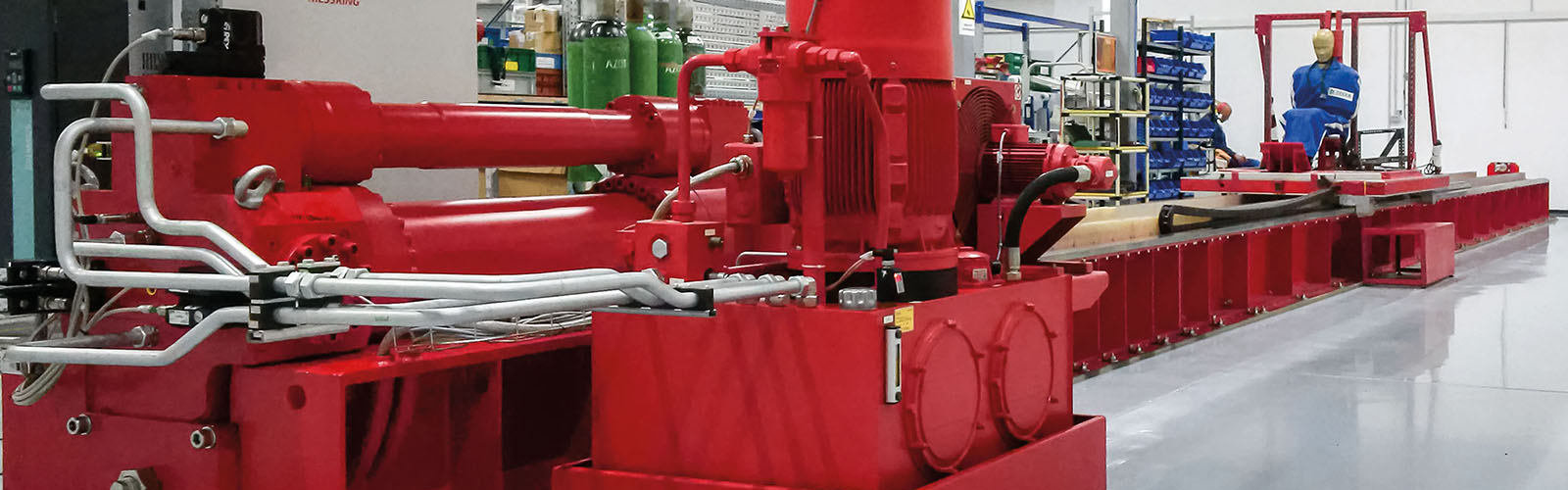

During the test runs, a seat construction with dummy is fixed to the sled and accelerated in a controlled process using a hydraulic cylinder. Depending on the payload and acceleration curve, top speeds of up to 82 kilometers per hour are possible. After the pulse, the sled is brought to a stop in a controlled process using a wear-free brake. MESSRING’s integrated M=BUS data acquisition system transmits the results directly to the CrashSoft control software. Also developed by MESSRING, this software combines the diverse setting characteristics of the facility and displays the results in a simple and clear format on a computer screen.

“We started out with just one shift and an average of seven tests in 2014. We now work in three shifts with an average of eight tests per shift,”

Milan Novak, Head of the Testing and Validation team at Takata Romania

“The CIS allows us to reproduce the same pulse with 90% reliability in two or more consecutive tests,” says Novak. The acceleration process stipulated in the test regulations can be reproduced with identical results over and over again despite four years of continuous use. Fluctuations in the oil temperature, abrasion on sliding parts, and wear on the drive valves and mechanical parts are minimal and therefore do not have a significant impact on the sled test facility’s performance data. An air conditioner in the hall maintains a constant temperature, which also has a positive effect.

Every six months, MESSRING engineers inspect and maintain the facility, ensuring it operates as it should. The piston accumulator seal didn’t have to be replaced until after 7,000 tests. Over the past four years, the facility has never stood idle for more than four or five days at a time, which is another reason for the unusually high number of test runs carried out.