Innovative mount for the CIS sled-testing system fulfills all of the regulation’s testing requirements for the approval of child restraint systems / side-impact test at 25 km/h.

Munich, December, 2017 – MESSRING has expanded its range of mounts for its CIS (Compact Impact Simulator) sled-testing system. Effective immediately, the world’s leading manufacturer of crash test facilities and their components is offering its own mounting system to test child restraint systems pursuant to the new UN ECE R129 regulation, which enters force in 2018. In addition to front and rear-impact testing, the amended regulation governing the approval of child restraint systems now also requires side-impact testing for the first time.

MESSRING will supply the new mount as a ready-to-use system which allows car seat manufacturers to carry out all testing in accordance with the new regulation quickly, easily, and with precision. It was developed for MESSRING’s CIS sled-testing system, but can also be used with other sled-testing systems. “The new regulation significantly tightens the requirements that manufacturers must meet in order for their child restraint systems to be approved for use in the EU,” said Dierk Arp, CEO of MESSRING. “With our new mounting system, we are launching the first integrated solution that meets all of the associated testing requirements.”

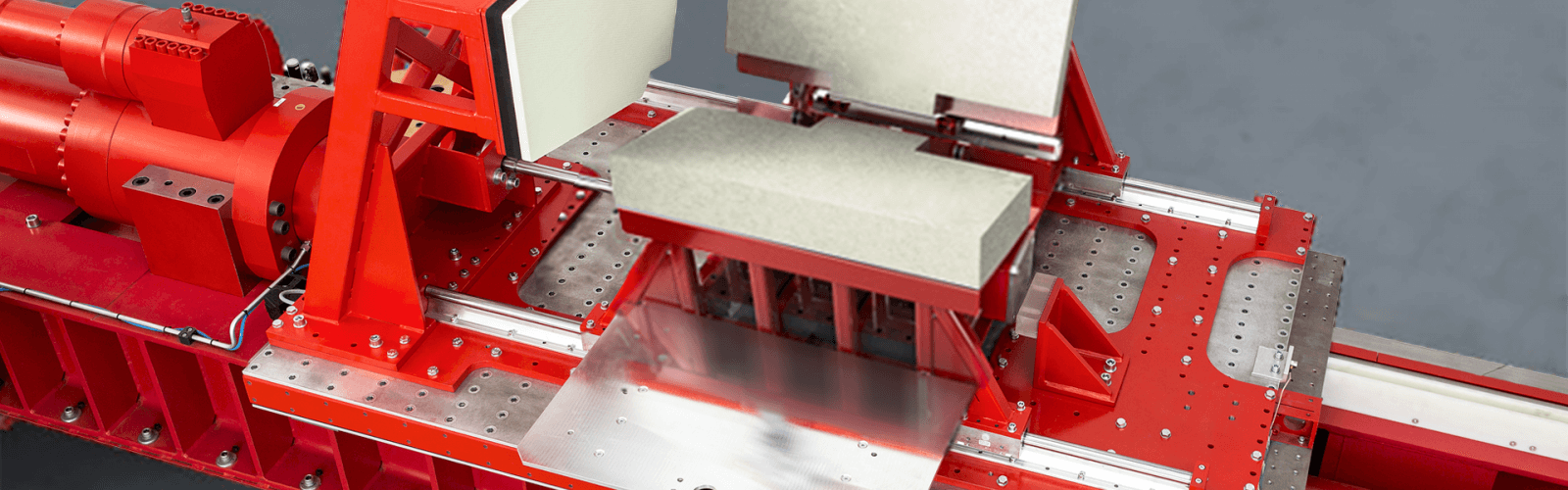

The seat mounting system can be used for front, rear, and side-impact testing of child restraint systems. To achieve this, MESSRING designed a completely new mount, including a damper system, door element, and bench seat. As such, all of the processes and crash phases defined by policymakers can be replicated and integrated into the sled tests. In this context, the bench seat to which the child restraint system is attached only needs to be turned around and adjusted. Within a distance of only 15 centimeters, the CIS accelerates the door panel to precisely 25 kilometers per hour, the speed stipulated for the side-impact test. Afterwards, it initiates deceleration. A damper system developed in-house is responsible for both the deceleration of the bench seat and the progression of the stipulated relative speed. The mounting system was designed to be vibration-resistant. Since the acceleration and deceleration values are controlled hydraulically, additional damping material is not required – only the Styrodur on the door panel needs to be replaced.

With the new mounting system for child restraint systems, MESSRING has once again expanded its already wide range of components and mounts for its CIS sled-testing system. There is currently no other concept on the market that is as flexible, variable, and covers such a variety of different use cases. The new car seat mounting system was developed over the course of nearly a year. The company plans to deliver the first of these systems to customers in China and Spain before the end of the year.